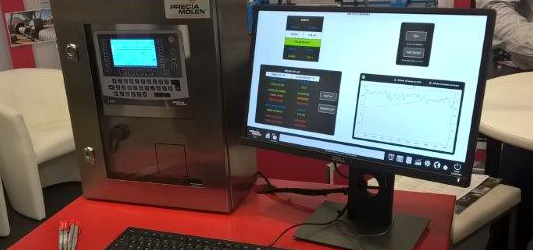

Weighing indicator I410

Industrial controller for weighing process

The I410 system provides a new solution to the issues encountered when integrating a weighing function to any industrial process.

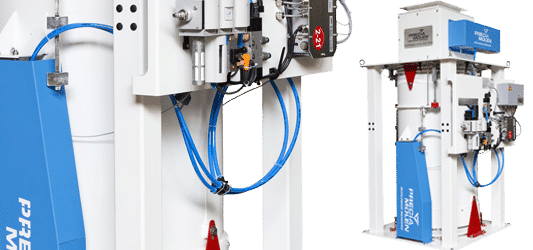

With a modular and distributed design, the I410 system is organized around the CANopen field bus, and comprises the following 3 main elements:

- a weight TRANSMITTER processing the signal close to the load cells for better immunity to electromagnetic disturbance. Some transmitter models even integrate the load cell junction box,

- a GRAPHIC TERMINAL associated with a weight transmitter per measurement channel managed (up to 31 channels),

- a COUPLER providing communication with the most common industrial field buses in the market: Profibus, DeviceNET, Ethernet TCP/MODBUS, Ethernet/IP and Profinet.

Additional modules:

- Local or remote digital Inputs/outputs,

- RS 232, RS422/485 and USB communication,

- Local or remote 4-20 mA or 0-10V analog inputs/outputs,

- USB flashdrive for weighing storage and traceability.

With high metrological performance (fast conversion, multi-range and powerful filtering algorithms), meeting the most demanding industrial processes.

All components, transmitters and terminals, can be installed directly in explosive area, without impacting performance while allowing communication with the safe area.

Including a PLC-oriented development workshop, compatible with the IEC 1131 standard, the I410 system allows to deploy basic or complex applications:

- “field” applications proposed by PRECIA MOLEN,

- data feeding into customer’s information system,

- specific development design.

Functions

Dedicated Software

The system equipped with I 410 ABS hopper scale software is the measuring and control device for PRECIA MOLEN hopper scales. The I 410 ABS system may also replace different indicators on existing installations. The I 410 ABS software may control any type of hopper scale: – hybrid with levers or 100% electronic, – with one or several filling gates.

The I 410 WBF command control and automatic power and regulation box allows monitoring a weigh belt feeder of any type: belt, screw or loss in weight. It can be adapted to a dual-channel version.

I 410 MDU software is suitable for most manufacturing processes for a finished or semi-finished product comprising different components in the proportions defined in a formula. This software can process the automatic creation of each of the doses with weight-based checks and stock management, providing complete manufacturing traceability.

The WMU Weighbridge weighing software ensures the management of any vehicle (road or railway) that requires weighing carried material. It manages up to 3 weighbridges (2 physical weighbridge and 1 summation bridge) with different capacities/divisions that combine accuracy and maximum capacity.

The I 410 PWS software enables the I 410 weight indicator to be integrated into an industrial process controlled by a PLC or a PC.

The I 410 GFS software is the measuring and slaving device developed by PRECIA MOLEN for controlling the single or dual weigh hopper gravimetric filling scale. Our electronic system equipped with I 410 GFS software can replace any type of existing built-in indicator in the semi-automatic or automatic bagging lines. In fact, this software allows measuring the weight and controlling one to two net or gross weighers-weighing bagging scales.

The I 410 CKW software fulfils most industry requirements for discontinuous dynamic weighing. – In motion weighing – Checking production tolerance – Weight classification – Checking order compliance – Checking prepacked goods – etc… Weighings can be obtained either dynamically or statically.

The I 410 SDU software satisfies most needs to produce a product dose by making a weight check in the industrial environment. It enables simultaneous management of 1 to 4 single constituent dosing processes.

The multiple-channel software I 410 MBS (multi-belt scale) has been designed to measure variable-capacity flows of all bulk products without any capacity limit. It is connected to transmitters (from 1 to 8). Each transmitter integrates a board measuring weight and acquires the running speed of the conveyor belt. The link between the terminal and the transmitters is ensured by a CAN Open fieldbus (up to 500 metres).

Single Belt Scale Software I 410 SBS for single-channel continuous weighing has been designed to measure variable-capacity flows of all bulk products without any capacity limit. It integrates a weight and conveyor belt speed acquisition measuring board.

The I 410 WLC software satisfies most needs in terms of level control and check in the industrial environment. It enables simultaneous control of 6 levels and 4 analogue outputs on 1 to 4 measurement channels. Independent parameter settings are possible for each level of each measurement channel.