In the food-processing industry, traceability guarantees food safety, whether it be quantitative or qualitative. Precia Molen offers a wide range of weighing and control solutions for each stage of your production. Our products are designed in compliance with the regulations applicable to the food-processing industry.

Ensure the traceability of raw materials right from their entrance on your site! Our weighbridges and our weighing platforms allow you to know the exact weight of the products you receive.

Then, organize the unloading and the storage of your food products. Our platforms (measurement channels, load cells, or crane scales) and our weight indicators ensure the close monitoring of your stocks. Our precision scales and laboratory scales help you with sample analysis, a key step in your quality process.

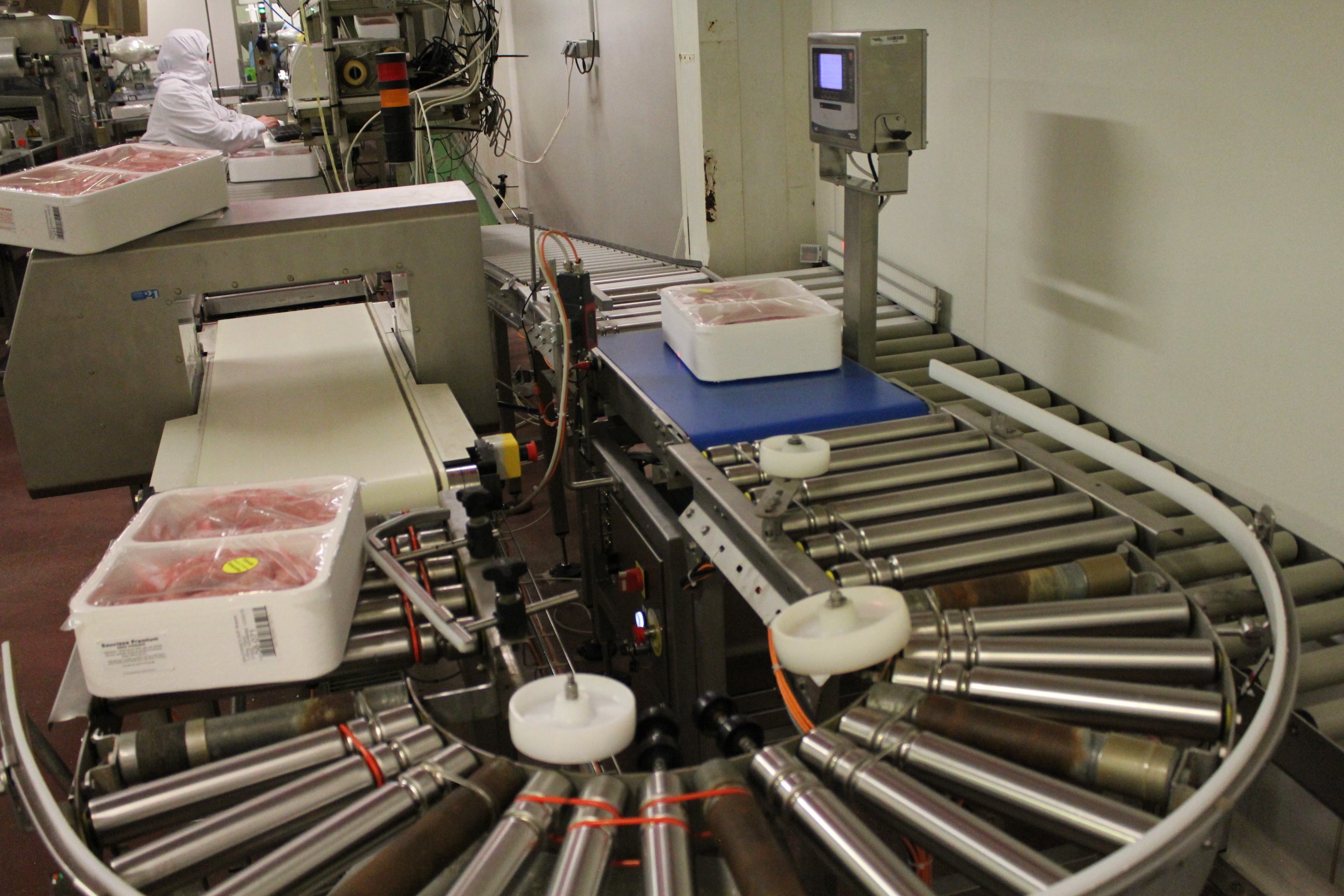

Checkweighers:

Checkweighers:  Automatic recipe control:

Automatic recipe control: